Trane New York / New Jersey

CUNY: Kingsborough Community College

Brooklyn, NY, Jul 30, 1997

Total Efficiency Improvement Key to College System Upgrade

|

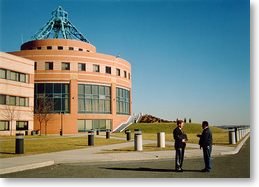

| The oceanside location and novel architecture make this campus a favorite for City University of New York activities. |

Serving a Wide Range of Students The college is one of the true jewels in the CUNY crown. Its roomy, oceanside campus and its ample parking and meeting facilities make it a favorite location for university-wide functions. But the primary role of the school is to provide a quality college education for a wide range of students. The college has innovative educational offerings including a Weekend College for non-traditional students and a wide range of two-year curricula leading to an associate degree or to placement in a bachelor's program in a four-year college.

The campus overlooks Rockaway Inlet and includes 16 academic and administrative buildings. One of the signature buildings for the college is the Marine Academic Center; a recent building topped off with an actual operating lighthouse. This building houses the business, secretarial science and nursing departments as well as many computer labs. As an example of the progressive thinking of this college, the building also houses a child day care center for students. Other prominent buildings include the Administration Building, library, gymnasium, and the Arts and Science Building.

Central Plant Serves Entire Campus

|

| A new remote annunciator panel makes monitoring system status easier. |

There were four cooling towers, each with three 50-horsepower motors operating in a split configuration. The towers were used for system steam condensing as well as heat exchangers for the chiller condensing water. They were in reasonably good condition, though somewhat undersized given the steam condensing load from the turbines. According to senior engineer Anthony Corazza, "The steam turbine machines put an extra load on the cooling towers, especially on warm, humid days. We were running at tower capacity on those days, even though the chillers weren't fully loaded."

Oceanside Humidity a Factor Corazza points out that, with the steam turbine system, the chilled water plant was occasionally limited by head pressure, sometimes as high as 16 pounds. Because of its oceanside location, the campus has a good share of high-humidity days. On those days, the system was limited by tower capacity and could not keep up.

For these reasons, Krapf performed an economic analysis of system options. The decision was made to replace the two 20-year old steam turbine chillers with higher efficiency electric centrifugal machines. The proposed project also involved replacing the original condensate and chilled water pumps with newer, more efficient variable speed designs. "Good variable speed pumps are a real advantage in a situation like this," says Krapf.

Trane Chosen for HVAC Upgrade

|

| Three Trane CenTraVacŪ Model 1100-ton chillers were selected to replace steam turbine equipment. |

|

| New pumps and motors were included with the project. |

The college wanted to be able to generate chilled water in the 44°F range to achieve maximum dehumidification. According to Corazza, "We wanted to get the humidity levels down to improve the comfort of building occupants. The best way to do that was to keep the chilled water temperature down." Corazza and Krapf indicate that the new system is accomplishing that goal, while also reducing system energy use.

|

| New chillers were equipped with gantries to facilitate removal of endplates for the tube cleaning. |

In 1997, the college peak load was about 2,400 tons and could actually be carried by two of the three new electric machines. In addition, the goal of more effective dehumidification was also achieved. For the time being, Kingsborough Community College finally has surplus chilled water system capacity. Krapf says, "It's good to know we have that. It allows for future growth."

[Read More]